Certification: ISO 9001 Certified

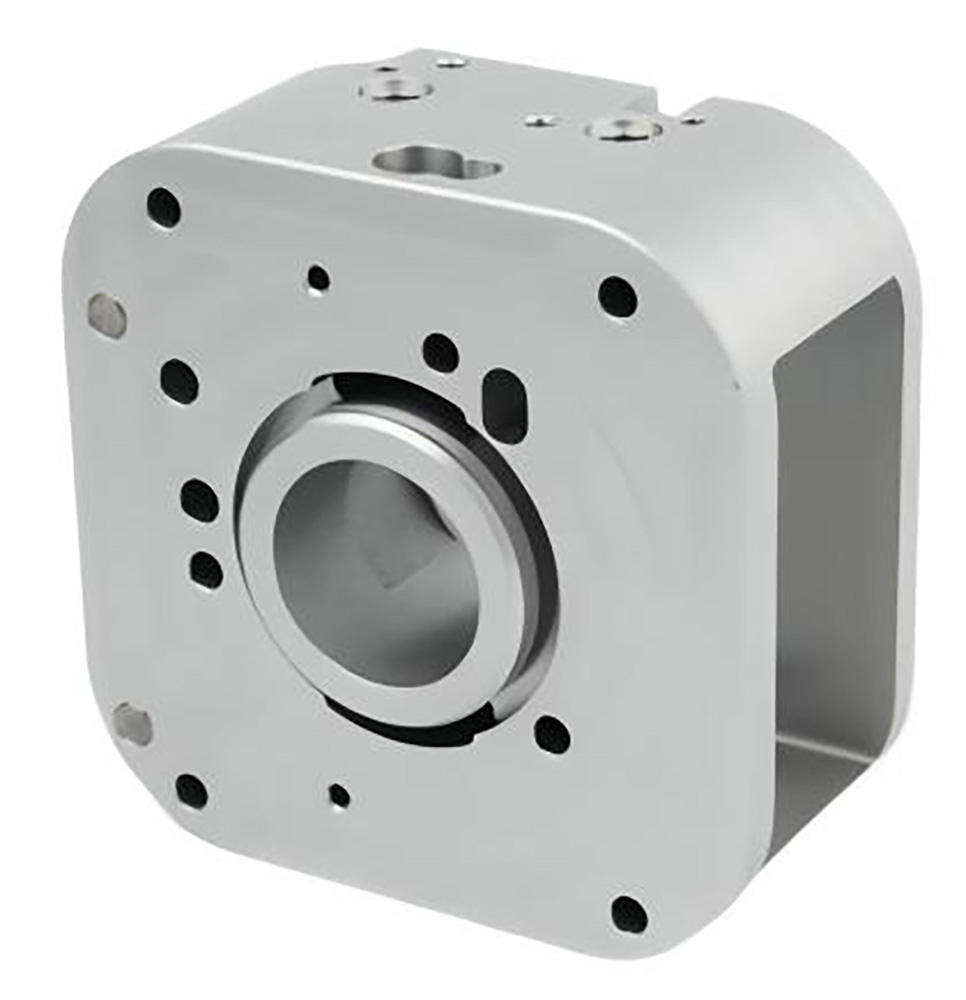

Industry Focus: Medical Devices, Instruments, Diagnostic Tools

Material: Medical-grade Aluminum Alloy

Machining Type: CNC Milling, Turning, 5-Axis Machining

Surface Finishes: Anodized (Red, Blue, Green, Purple, Gold, Black, Natural), Polished, Sandblasted

Color Options: 10+ Custom Colors Available

Tolerance: ±0.005mm

Batch Volume: Prototyping to 100,000 Units

OEM/ODM: Supported with NDA

Component Types: Housings, Brackets, Flanges, Couplings, Rotary Knobs

Threading: Metric & Imperial

CAD/CAM Software: SolidWorks, UG, MasterCAM

File Support: STEP, IGES, DWG, STL

Edge Quality: Chamfered, Rounded, Deburred

Finish Thickness: Anodized 10-25μm

Dimensions: Custom up to 300mm

Design Feedback: DFM Analysis Included

Lead Time: 5–12 Days

MOQ: 1 Piece

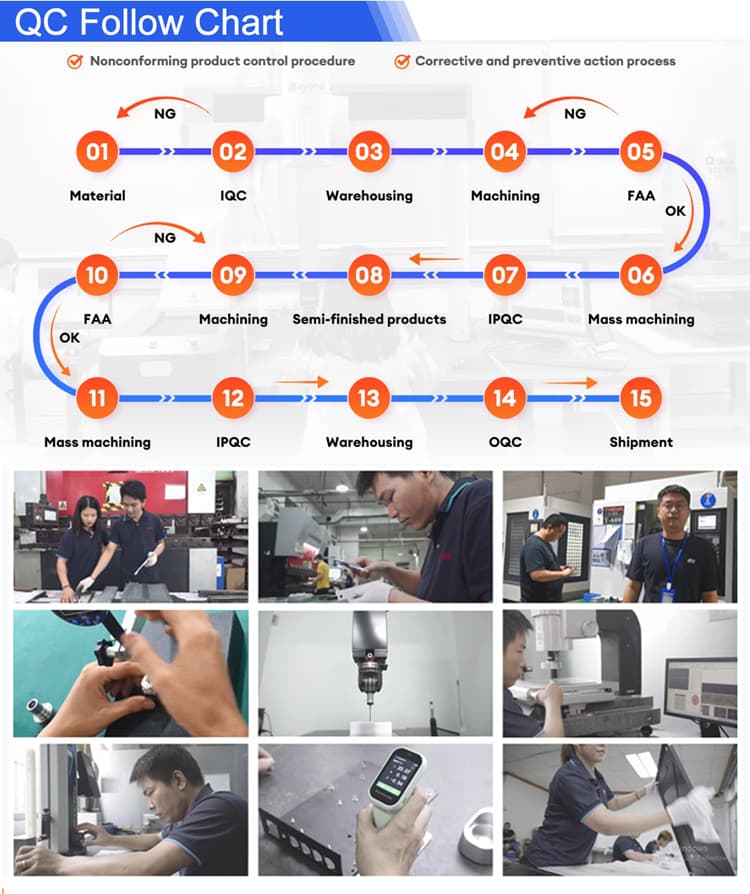

Inspection: Full QC with Report

Medical Compliance: Biocompatible Coatings Optional

Fixture Design: Precision Fixturing for Repeat Accuracy

Assembly: Optional Sub-Assembly Services

Engraving: Laser Marking (e.g., QR Code, Serial No.)

Logo Placement: Custom Branding Supported

Shipping: FedEx, DHL, UPS, Air/Sea

Packaging: Medical-grade Clean Bag or Foam Protection

Corrosion Resistance: Excellent via Anodizing

Heat Resistance: Up to 120°C (Coated)

Environmental Compliance: RoHS, REACH

Tool Type: Micro-End Mills, Chamfer Tools, Reamers

Precision Cavity: Complex Internal Cavities Supported

Surface Roughness: Ra 0.4–1.6μm

Machining Repeatability: ±0.003mm

Measurement Tools: CMM, Profile Projector, Micrometer

High Visibility Parts: Color-Coded Options

Polished Finish: Mirror Finish Optional

Micro Milling: Yes (small features

<0.5mm)< li="">Online Quotation: Available within 24h

Support Team: Engineering + Sales Follow-up

Factory Type: Precision CNC Machining Facility

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-