CNC Part Fabrication - Aluminum CNC Precision Machining Contractor

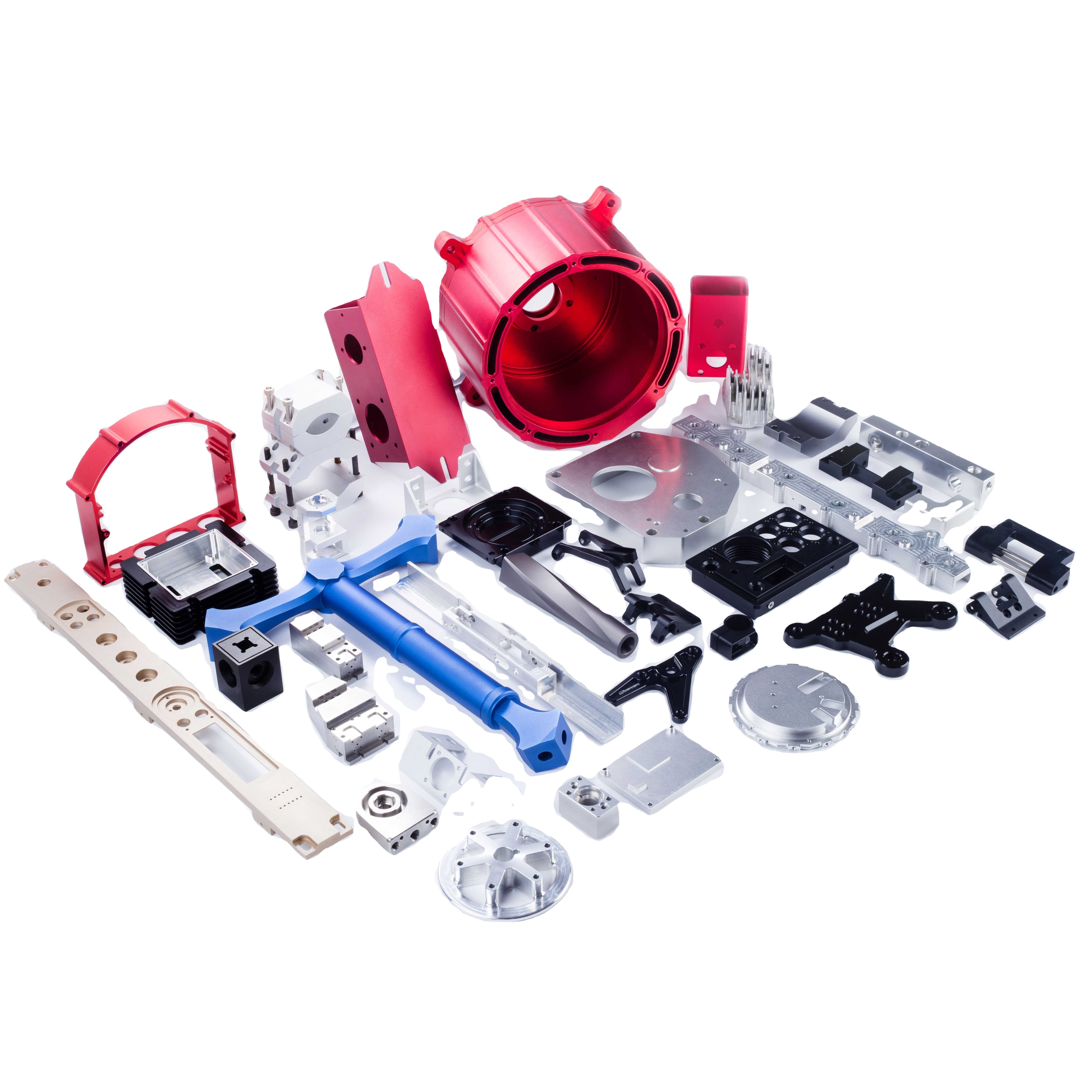

Tailored surface treatment options for your aluminium parts

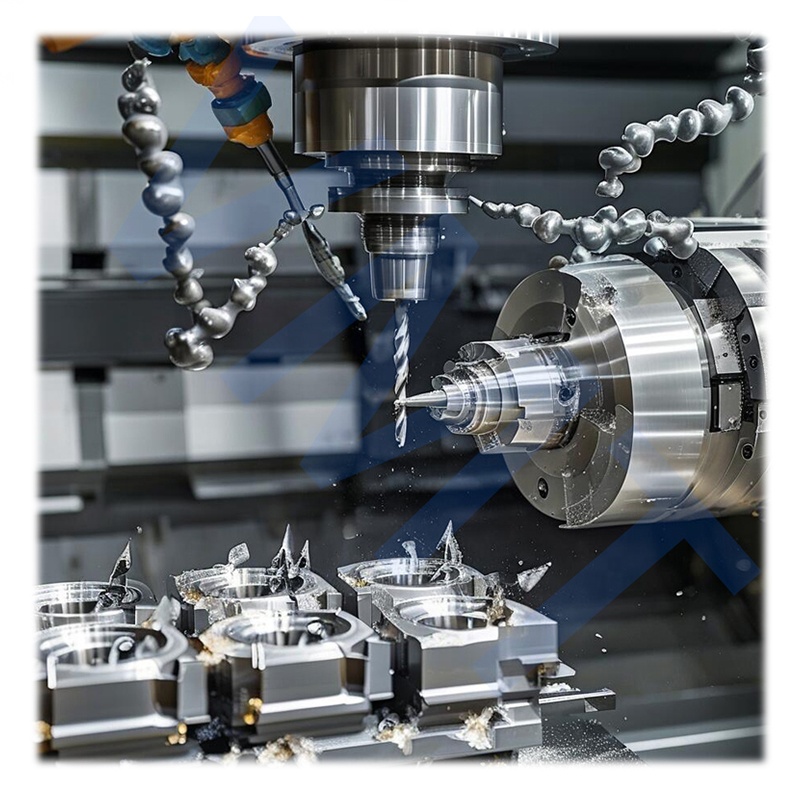

CNC Machining or Not: Cnc Machining

Type: Laser Machining, Milling, Other Machining Services, Turning, Aluminum Extrusion Profiles/CNC Machining Parts

Material Capabilities: Aluminum

Micro Machining or Not: Micro Machining

Place of Origin: Guangdong, China

Model Number: CNC

Brand Name: Liangyin

Size: Customer's Drawing Required

Material: 6061/6063 Aluminum Alloy

Length: Custom Size

Thickness: 0.6mm - Customized

Surface treatment: Mill Finish,Power Coated, Anodized, etc

Color: Sliver, Gold, Black, Red, Custom

Certification: ISO9001:2015, Rohs

MOQ: 500 Kgs

Payment term: T/T,L/C

Custom CNC Milling Turning Parts Aluminum Machining Service High Precision 3 Axis 4 Axis 5 Axis CNC Components Precision Parts | ||

Precision Service | Aluminum Extruded,CNC Turning Services,CNC Milling Services, 3-Axis/4-Axis/5-Axis CNC Machining, Surface Finishing Service | |

Customized Service | Bespoke Extrutions Tooling and Dies, 3D drawing, Color Customize, Logo Custom | |

Fabrication Service | Aluminum Extrusions, Aluminium parts, Aluminium Sheets | |

Solution Service | Support Design from Aluminum Profiles Extruded to deep progress CNC Machining for a Contract project or a new design. | |

Materials | We focus on Aluminum aloy. 6063,6061,6005,6082,5052,other materials we also support. | |

SHAPE | square, round, shaped, rectangular, customized |

APPLICATION | furniture, windows&door, decorations, industry, constructions, and so on |

SURFACE TREATMENT | mill finish, anodizied, powder coating, fluorine carbon spraying, and so on |

COLORS | silver, black, blue, wood color, RAL powder coating color and so on |

DEEP PROCESS | CNC, drilling, milling, cutting, bending, assembling |

PACKING DETAILES | Inside: packed with plastic protective film to protect each piece Outside: wrap to be bundles by waterproof craft paper |

DELIVERY TIME | Mass production completed: 20-30 days after sample is comfirmed by client |

FOB PORT | FOSHAN/SHENZHEN/GUANGZHOU |

PAYMENT TERMS | T/T 30% for deposit, balance before shipping |

PRODUCTION CAPACITY | 5000 tons monthly, 60000 tons annualiy |

CERTIFICATES | SGS, CE, ISO, QUOLANOD AVAILABLE |

GRADE | 6063 | 6061 | 6463 | 3003 | |||

STANDARD | GB/T 3190-1996 | ||||||

Al | Remain | Remain | Remain | Remain | |||

Si | 0.2-0.6 | 0.4-0.8 | 0.2-0.6 | <=0.6 | |||

Cu | <=0.1 | 0.15-0.4 | <=0.2 | 0.05-0.2 | |||

Mg | 0.45-0.9 | 0.8-1.2 | 0.45-0.9 | / | |||

Zn | <=0.1 | <=0.25 | <=0.05 | <=0.1 | |||

Mn | <=0.1 | <=0.15 | <=0.05 | 1.0-1.5 | |||

Ti | <=0.1 | <=0.15 | / | / | |||

V | / | / | / | / | |||

Fe | <=0.35 | <=0.7 | <=0.15 | <=0.7 | |||

Cr | <=0.1 | 0.04-0.35 | / | / | |||

SINGLE | 0.05 | / | 0.05 | 0.05 | |||

TOTAL | 0.15 | / | 0.15 | 0.15 | |||

Custom CNC Milling & 5 Axis CNC Machining Services – Precision Aluminum Parts ISO 2768-M&K

ISO 9001 Certified 5-Axis CNC Machining Manufacturer High Precision Custom Parts

5-Axis CNC Precision Machined Parts Multi-Material Custom High Accuracy Components

CNC Machining or Not: Cnc Machining

Type: Broaching, DRILLING, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys, Steel Machining Services

Micro Machining or Not: Micro Machining

Place of Origin: Guangdong, China

Model Number: cnc machining services

Brand Name: VMT cnc custom part

product name: cnc machining service

Material: Aluminum, Brass, Copper, Titanium, Stainless Steel, Steel Alloys, POM

Processing Type: CNC Turning, CNC Milling, CNC Machining, Grinding, EDM Wire Cutting

Surface treatment: Painting\Powder Coating\Plating\Polishing

Logo Methold: CNC Engraving, Laser Engraving, Screen-Printing

Certification: ISO9001:2008/TS 16949

Application: Machine Industrial equipment Auto Medical Auto parts

company address: Shenzhen Guangdong. China

Serve: Brass Aluminium Stainless cnc machining

delivery time: 7-15 davs