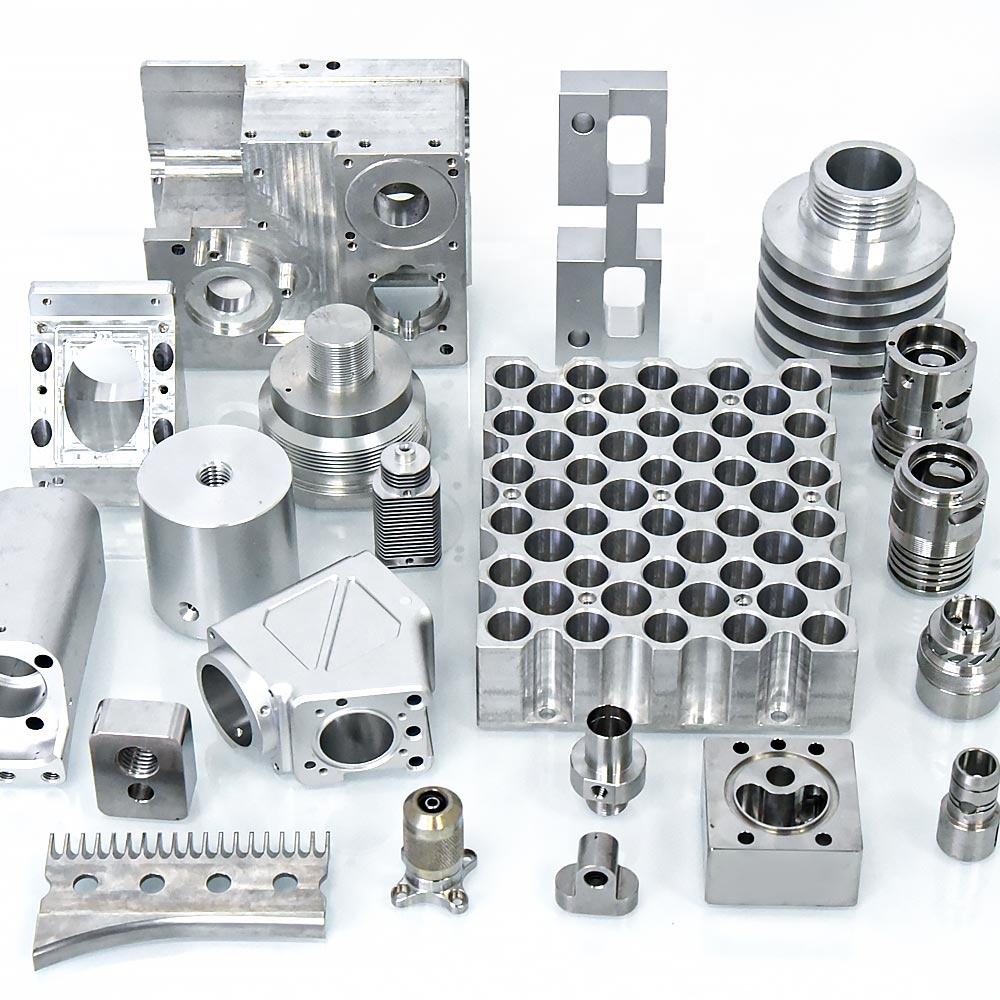

Custom 5 Axis CNC Machining Precision Metal Parts – Product Details

Material: Aluminum, Stainless Steel, Copper, Brass, Alloy Steel

Processing Type: 5 Axis CNC Machining, CNC Milling, CNC Turning

Precision Tolerance: ±0.01mm

Surface Finish: Polished, Anodized, Sandblasted, Brushed, Plated

Shape: Complex and custom geometries

Size: Fully customizable

Application: Aerospace, Automotive, Electronics, Robotics, Medical Devices, Industrial Equipment

Corrosion Resistance: Excellent

Strength: High tensile and yield strength

Hardness: Material-specific hardness levels

Weight: Lightweight for aluminum, heavier for steel

Thermal Conductivity: High for copper and aluminum

Electrical Conductivity: High for copper and brass

Machinability: Suitable for intricate designs

Production Volume: Prototypes and mass production

MOQ: Flexible

Lead Time: 7-15 days

Design Support: CAD/CAM engineering

Customization: OEM & ODM available

Edge Treatment: Deburring, chamfering

Hole Drilling: Precision drilling

Threading: Internal and external threading

Assembly: Optional

Packaging: Protective packaging

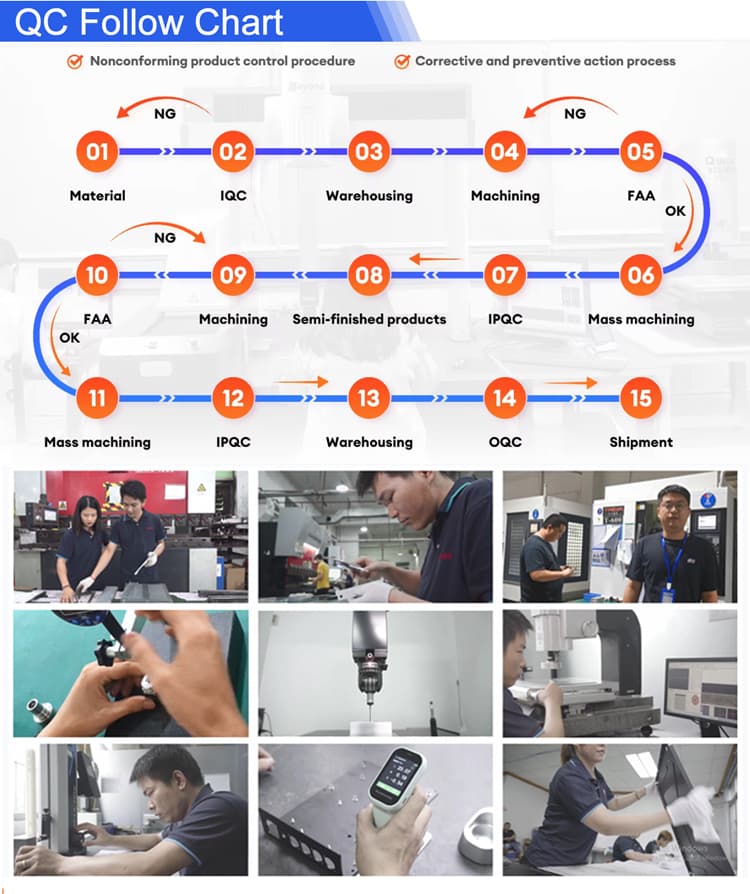

Certification: ISO9001, ISO14001, RoHS

Heat Treatment: Optional

Wear Resistance: Enhanced

Surface Smoothness: Ra 0.8-1.6μm

Compatibility: Fits multiple industrial uses

Dimensional Stability: Maintained under stress

Impact Resistance: High

Environmental Resistance: UV and moisture

Operating Temperature: -40°C to +200°C

Recyclability: 100% recyclable metals

Design Complexity: Supports intricate 5 axis designs

Machining Speed: High efficiency

Fixture Type: Custom fixtures

Inspection: 100% QC before shipment

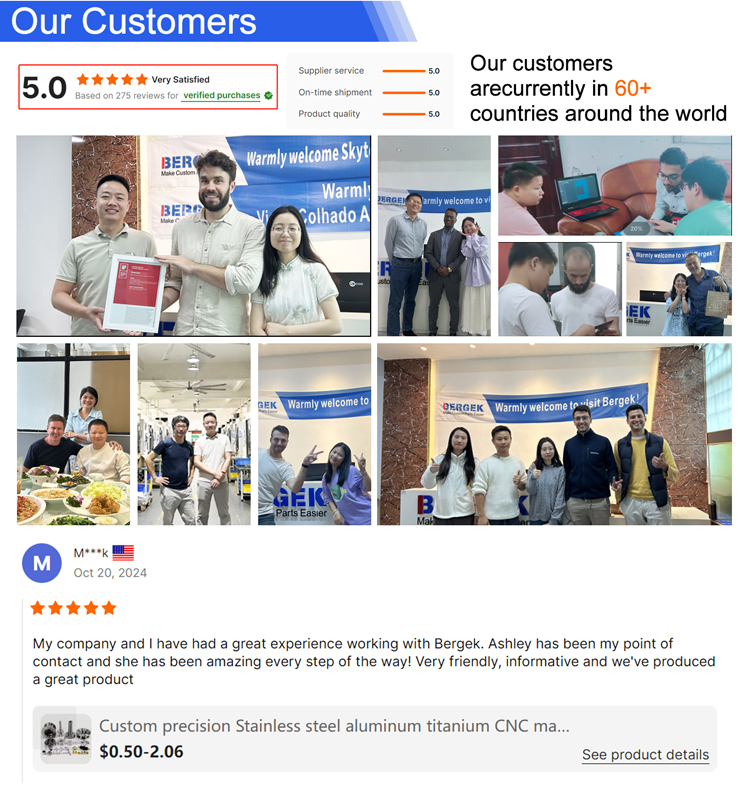

After-sales Service: Full technical support

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-