Description

CNC Machining or Not: Cnc Machining

Type: Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM

Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys

Micro Machining or Not: Micro Machining

Place of Origin: Guangdong, China

Model Number: cnc machining steel

Brand Name: cnc machining cnc parts

Material: stainless steel , Aluminum , Brass , titanium

Process: Milling , turning CNC parts

Product name: cnc machining service parts cnc machining

Application: Industrial Equipment

Service: One stop service. Machining-assembly

Keyword: machinery industrial parts

Process kind: custom cnc parts

Surface treatment: anodizing polishing plating painting

Name: Customized Machined CNC Machining industrial parts

Item: Precision CNC Machining Parts

CNC Machining Capability

CNC Milling Processing

Our CNC milling services can produce highly accurate and complex parts from a variety of materials, including metals, plastics,and composites.

Machinery Axis: 3,4,5,6

Tolerance:+/- 0.01 mm

Special Areas: +/-0.005 mm

Surface Roughness: Ra 0.1~3.2

Supply Ability:300000 Piece/Month

CNC Turning Processing

OEM&ODM

Customized Precision Parts

1-Piece minimum order

3-Hour quotation

Samples: 1-3 Days

Lead time: 7-14 Days

QC team, inspection

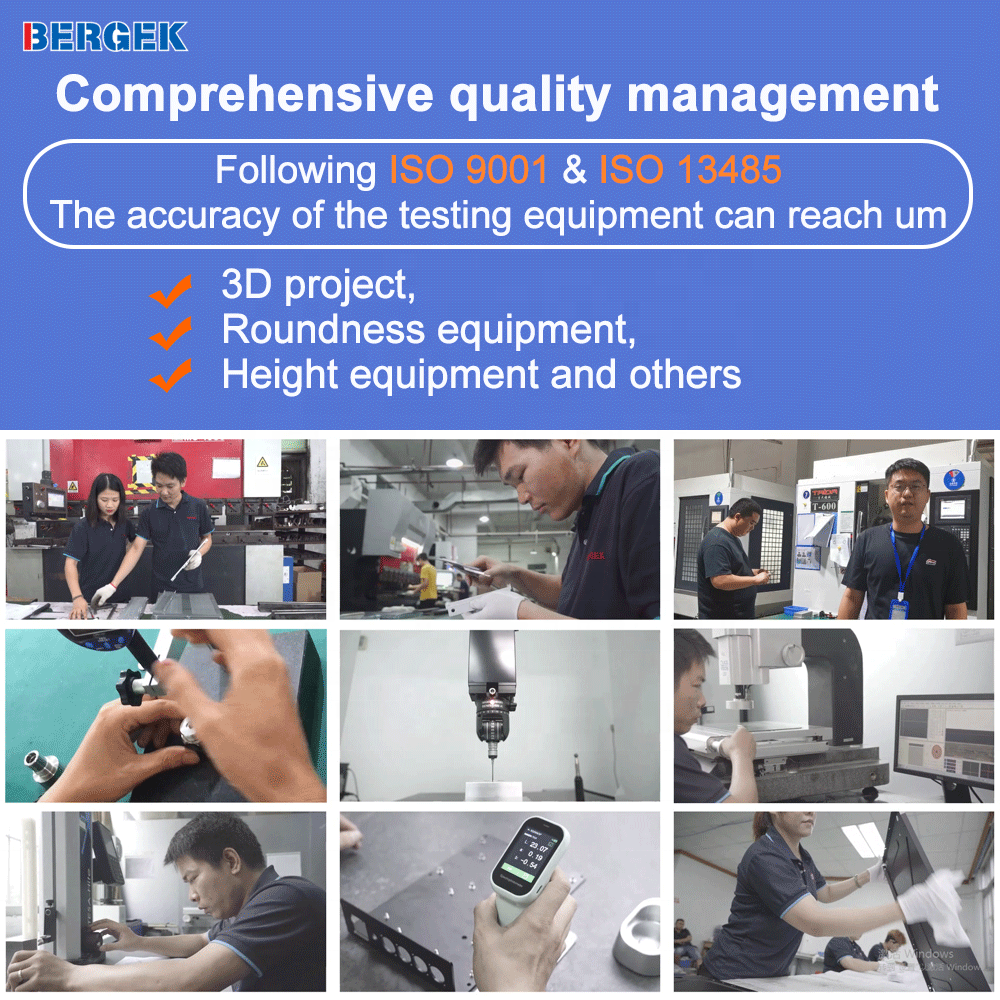

We are proud to hold several production certificates for our CNC machining services, which demonstrates our commitment to quality and customer satisfaction. Our team follows strict quality control procedures to ensure that every part we produce meets the highest standards of quality and accuracy.

Laser cutting

BySprint Fiber

Laser cutting machine 2 sets

Cutting range :4000*2000 mm

Sheet Metal Fabrication

8 CNC Bender

Daily output: 115200 bents

Tolerance range: 0.01-0.05mm

Plastic injection Molding

Not only a detailed quotation

but also an initial DFM

and Mold Flow analysis

How Can BERGEK Help You with CNC Machined Parts?

Are you searching for reliable CNC machining manufacturers who can deliver high-quality parts and services?

Comprehensive Services

From rapid prototyping to mass production, BERGEK provides a one-stop CNC machining service, integrating Casting, 3D printing, laser cutting, welding, plastic injection molding and more. Save up to 30% in costs with our efficient processes.

Professional Surface Treatments

With 50+ surface effects available, including anodizing, powder coating, and polishing, our mature quality control ensures high standards for your CNC machined parts.

Proven Quality

quality checks ensure a 99.98% shipping pass rate.

Robust Capacity

Monthly production capacity: 500,000 pieces.

Product protection shield -- customized packaging

Protect the product and deliver it to you safely

Delivery & Shipping

DHL/UPS/FEDEX/TNT/OCS is shipped by default. If the customer has demand, We can also choose express delivery according to the customer's requirements.

Generally, it takes 3 days to send the express to Japan, and 4-5 days to Europe and America. This is mainly for small pieces (within 300kg).

For large parts, we will use air or sea transportation according to customers' requirements. Generally, it takes 4-5 days to ship to Japan by air and 7-10 days to ship by sea. It takes 7-10 days to ship the goods by air in Europe and America, and 15-20 days to ship the goods by sea.

What surface treatments do you typically perform on machined parts?

We have Full Suite of Professional Finishing Services . We make them better by applying a variety of treatments to improve their appearance, performance and durability. Contact us to learn more about our major finishing services .

What are the commonly used CNC machining Parts materials?

CNC Machining Finishes | Plastic Materials | Metal CNC Machining Materials |

Standard (As-Milled) | ABS | CNC Machining Aluminum Alloys |

Bead Blast | Acrylic | CNC Machining Copper Alloys |

Tumbled | Delrin (Acetal) | CNC Machining Bronze Alloys |

Anodized (Type II Or Type III) | Garolite | CNC Machining Brass Alloys |

Titanium Anodize | HDPE | CNC Machining Stainless Steel Alloys |

PTFE Impregnated Hard Anodize | Nylon 6/6 | CNC Machining Steel Alloys |

Chem Film (Chromate Conversion Coating) | PC (Polycarbonate) | CNC Machining Titanium Alloys |

Passivation | PEEK | CNC Machining Zinc Alloys |

Powder Coat | Polypropylene | |

Electropolishing | PTFE (Teflon) | |

Electroless Nickel Plating | UHMW PE | |

Silver Plating | PVC | |

Gold Plating | ULTEM | |

Zinc Plating |

Q1: Is your organization committed to the concept of total quality management?

A: Yes, no matter whether in laser cutting, bending, or CNC machining, QC will conduct the first sample inspection and random inspection during the processing to ensure the quality of the products.

Q2: How many checks are performed on a project?

A: Usually, products will go through the following four inspections: incoming inspection, production first inspection, sampling inspection, and pre-shipment inspection. Among them, sampling inspection will be conducted multiple times

Q3: Will you be able to work with our engineering team to review drawings and provide quick, estimated pricing for desired changes?

A: Yes, our engineers respond very quickly. If there is anything to be modified in the product, we can offer you a new price as soon as you tell us.

Q4: What kinds of information do you need for a quote?

A: Kindly please provide the product drawing in PDF, and will be better if you can provide it in .dwg / .stp /. igs / .stl , Send drawing

Q5: What tolerances can Bergek achieve?

A: There is not a given set of tolerances that fits all processes and materials. In every case, the final tolerances on your part will depend on a number of factors, including but not limited to:

●Part size

●Design Geometry

●The number, type, and size of features

●Material(s)

●Surface finish

●Manufacturing process

Once your order is confirmed, we will review your design and provide a design for manufacturing review, pointing out any areas where we may not be able to achieve your desired tolerances. It’s helpful if you can specify which areas in your design have critical tolerances that must be met and which can be slightly modified if needed to reduce the time and costs involved. Here are some general tolerance guidelines:

General tolerances for CNC machining in metal and plastic Refer to DIN ISO 2768 All manufacturing and technical specifications need to be clearly specified in the 2D drawings in order to be followed.

Q6: Will your company sign an NDA?

A: Yes, We will strictly follow the confidentiality agreement to protect the rights and interests of our customers

Q7: OEM/ODM customer’s logo printed is available?

A: YES, OEM/ODM, customer’s logo welcomed.

Q8: if we don’t have a shipping forwarder in China, would you do this for us?

A:We can offer you the best shipping line to ensure you can get the goods timely at the best price.

- User name Member Level Quantity Specification Purchase Date

Total 0 Record

- Satisfaction :

-

No evaluation information

Bergek is a world-class factory specializing in providing on-demand metal and plastic parts through CNC machining, sheet metal fabrication and injection molding. The company is located in the western part of Shenzhen city and has a factory area of over 9000 square meters. The company has obtained ISO9001 and ISO14385 certifications.

Quick Link

Contact Us

1st Floor, Building D, No. 30 Shijing Road, Lougang Street, Songgang District, Baoan District, Shenzhen, Guangdong, China

Industries

Aerospace